| 油泵:YG型不锈钢防爆管道油泵 |

放大图片 | |

YG型防爆管道油泵设计制造符合美国石油学会API610(一般炼厂用离心泵标准)和GB3215-82《炼厂化工及石油化工流程用离心泵通用技术条件》的有关规定。、 可以不建泵房,在室外工作。 2、 进出口法兰在同一中心线上,可直接安装管路上,立式结构,机泵一体,占地面积小,安装十分方便。 3、 采用优质机械密封,毫无泄漏,有效的减少了泵房的油气含量,心头了工作环境提高了泵房工作的安全可靠性。 4、 选用防爆等级为DIIBT4的EX防爆电动机。材质:铸铁、不锈钢。

YG型立式管道离心油泵工作条件

1、吸入压力≤1.0MPa,或泵系统zui高工作压力≤1.6MPa,即泵吸入口压力+泵扬程≤1.6MPa,泵静压试验压力为2.5MPa,订货时请注明系统工作压力。泵系统工作压力大于1.6MPa时应在订货时另行提出,以便在制造时泵的过流部分和联接部分采用铸钢材料。

2、环境温度<40℃,相对湿度<95%。

3、所输送介质中固体颗粒体积含量不超过单位体积的0.1%,粒度>0.2mm。

注:如使用介质为带有细小颗粒,请在订货时说明,以便厂家采用耐磨式机械密封。

立式管道油泵产品特点:

1、可以不建泵房,在室外工作。

2、进出口法兰在同一中心线上,可直接安装在管道上,立式结构机泵一体,占地面积小,安装方便。

3、采用优质机械密封,轴端无泄漏,有效地减少了泵房的油气含量,改善了工作环境,提高泵高工作的安全可靠性。

4、关键零部件选用优质新型材料,根据输送介质的腐蚀性和温度要求,提高了泵的工作可靠性和使用寿命。

5、选用防爆等级为dIIBT4的EX防爆电动机,具有优良的防爆性能。

YG型管道油泵主要用途

1、YG型管道油泵适用于输送不含固体颗粒的介质,如汽油、煤油、柴油等石油产品,温度为-20℃∽+120℃;

2、所输送油类介质温度T>120℃或含有微量颗粒时,可选择高温结构或化工泵结构。

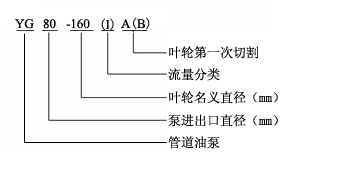

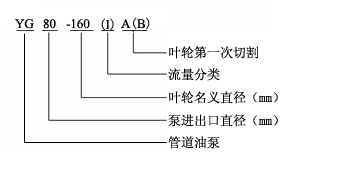

YG型立式管道离心油泵型号意义:

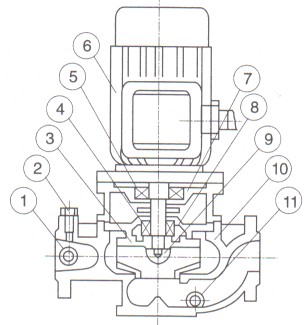

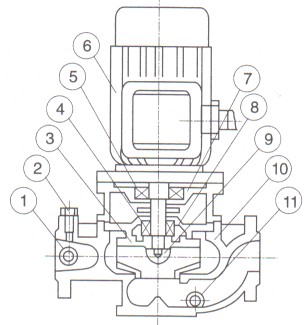

YG型立式管道离心油泵结构图:

1、取压阀 2、排气阀 3、叶轮 4、机械密封 5、轴承

| 管道油泵性能参数(1) |

| 型 号 | 流 量Q | 扬程

(m) | 效率

(%) | 转速

(r/min) | 电机功率

(KW) | 允许汽蚀余量

(m) | | (m3/h) | (l/s) | | 20-160 | 2.5 | 0.69 | 32 | 25 | 2900 | 0.75 | 2.3 | | 25-110 | 4 | 1.11 | 15 | 42 | 2900 | 0.55 | 2.3 | | 25-125 | 4 | 1.11 | 20 | 36 | 2900 | 0.75 | 2.3 | | 25-125A | 3.6 | 1.0 | 16 | 35 | 2900 | 0.55 | 2.3 | | 25-160 | 4 | 1.11 | 32 | 32 | 2900 | 1.5 | 2.3 | | 25-160A | 3.7 | 1.03 | 28 | 31 | 2900 | 1.1 | 2.3 | | 32-100 | 4.5 | 12.5 | 12.5 | 44 | 2900 | 0.55 | 2.3 | | 32-100(I) | 6.3 | 1.75 | 12.5 | 54 | 2900 | 0.75 | 2.3 | | 32-125 | 5 | 1.39 | 20 | 44 | 2900 | 0.75 | 2.3 | | 32-125A | 4.5 | 1.25 | 16 | 43 | 2900 | 0.55 | 2.3 | | 32-160 | 6.5 | 5 | 32 | 44 | 2900 | 1.5 | 2.3 | | 32-160A | 4 | 1.1 | 25 | 34 | 2900 | 1.1 | 2.0 | | 32-160(I) | 6.3 | 1.75 | 32 | 40 | 2900 | 2.2 | 2.0 | | 32-200 | 4.5 | 12.5 | 50 | 32 | 2900 | 3 | 2.0 | | 32-200(I) | 6.3 | 1.75 | 50 | 33 | 2900 | 4 | 2.0 | | 32-200A | 4 | 1.11 | 44 | 40 | 2900 | 2.2 | 2.0 | | 40-100 | 6.3 | 1.75 | 12.5 | 54 | 2900 | 0.55 | 2.3 | | 40100A | 5.6 | 1.56 | 10 | 52 | 2900 | 0.37 | 2.3 | | 40-125 | 6.3 | 1.75 | 20 | 46 | 2900 | 1.1 | 2.3 | | 40-125A | 5.6 | 1.56 | 16 | 45 | 2900 | 0.75 | 2.3 | | 40-160 | 6.3 | 1.75 | 32 | 40 | 2900 | 2.2 | 2.3 | | 40-160A | 5.9 | 1.64 | 28 | 39 | 2900 | 1.5 | 2.3 | | 40-160B | 5.5 | 1.53 | 24 | 38 | 2900 | 1.1 | 2.3 | | 40-200 | 6.3 | 1.75 | 50 | 33 | 2900 | 4 | 2.3 | | 40-200A | 5.9 | 1.64 | 44 | 31 | 2900 | 3 | 2.3 | | 40-200B | 5.3 | 1.47 | 36 | 29 | 2900 | 2.2 | 2.3 | | 40-250 | 6.3 | 1.75 | 80 | 28 | 2900 | 7.5 | 2.3 | | 40-250A | 5.9 | 1.64 | 70 | 28 | 2900 | 5.5 | 2.3 | | 40-250B | 5.5 | 1.53 | 60 | 27 | 2900 | 4 | 2.3 | | 40-100(I) | 12.5 | 3.47 | 12.5 | 62 | 2900 | 1.1 | 2.3 | | 40-100(I)A | 11 | 3.05 | 10 | 60 | 2900 | 0.75 | 2.3 | | 40-125(I) | 12.5 | 3.47 | 20 | 58 | 2900 | 1.5 | 2.3 | | 40-125(I)A | 11 | 3.05 | 16 | 57 | 2900 | 1.1 | 2.3 | | 40-160(I) | 12.5 | 3.47 | 32 | 52 | 2900 | 3 | 2.3 | | 40-160(I)A | 11.7 | 3.25 | 28 | 51 | 2900 | 2.2 | 2.3 | | 40-160(I)B | 10.4 | 2.89 | 22 | 50 | 2900 | 1.5 | 2.3 | | 40-200(I) | 12.5 | 3.47 | 50 | 46 | 2900 | 5.5 | 2.3 | | 40-200(I)A | 11.7 | 3.25 | 44 | 45 | 2900 | 4 | 2.3 | | 40-200(I)B | 10.6 | 2.94 | 36 | 44 | 2900 | 3 | 2.3 | | 40-250(I) | 12.5 | 3.47 | 80 | 38 | 2900 | 11 | 2.3 | | 40-250(I)A | 11.6 | 3.22 | 70 | 38 | 2900 | 7.5 | 2.3 | | 40-250(I)B | 10.8 | 3.0 | 60 | 37 | 2900 | 7.5 | 2.3 | | 40-250(I)C | 10.0 | 2.78 | 52 | 36 | 2900 | 5.5 | 2.3 | | 50-100 | 12.5 | 3.47 | 12.5 | 62 | 2900 | 1.1 | 2.3 | | 50-100A | 11 | 3.05 | 10 | 60 | 2900 | 0.75 | 2.3 | | 50-125 | 12.5 | 3.47 | 20 | 58 | 2900 | 1.5 | 2.3 |

立式管道油泵性能参数(2) | 型 号 | 流 量Q | 扬程

(m) | 效率

(%) | 转速

(r/min) | 电机功率

(KW) | 允许汽蚀余量

(m) | | (m3/h) | (l/s) | | 50-125A | 11 | 3.05 | 16 | 57 | 2900 | 1.1 | 2.3 | | 50-160 | 12.5 | 3.47 | 32 | 52 | 2900 | 3 | 2.3 | | 50-160A | 11.7 | 3.25 | 28 | 51 | 2900 | 2.2 | 2.3 | | 50-160B | 10.4 | 2.89 | 22 | 50 | 2900 | 1.5 | 2.3 | | 50-200 | 12.5 | 3.47 | 50 | 46 | 2900 | 5.5 | 2.3 | | 50-200A | 11.7 | 3.25 | 44 | 45 | 2900 | 4 | 2.3 | | 50-200B | 10.6 | 2.94 | 36 | 44 | 2900 | 3 | 2.3 | | 50-250 | 12.5 | 3.47 | 80 | 38 | 2900 | 11 | 2.3 | | 50-250A | 11.6 | 3.22 | 70 | 38 | 2900 | 7.5 | 2.3 | | 50-250B | 10.8 | 3.0 | 60 | 37 | 2900 | 7.5 | 2.3 | | 50-250C | 10.0 | 2.78 | 52 | 36 | 2900 | 5.5 | 2.3 | | 50-100(I) | 25 | 6.94 | 12.5 | 69 | 2900 | 1.5 | 2.5 | | 50-100(I)A | 22.3 | 6.19 | 10 | 67 | 2900 | 1.1 | 2.5 | | 50-125(I) | 25 | 6.94 | 20 | 68 | 2900 | 3 | 2.5 | | 50-125(I)A | 22.3 | 6.19 | 16 | 66 | 2900 | 2.2 | 2.5 | | 50-160(I) | 25 | 6.94 | 32 | 63 | 2900 | 4 | 2.5 | | 50-160(I)A | 23.4 | 6.5 | 28 | 62 | 2900 | 4 | 2.5 | | 50-160(I)B | 21.6 | 6.0 | 24 | 58 | 2900 | 3 | 2.5 | | 50-200(I) | 25 | 6.94 | 50 | 58 | 2900 | 7.5 | 2.5 | | 50-200(I)A | 23.5 | 6.53 | 44 | 57 | 2900 | 7.5 | 2.5 | | 50-200(I)B | 21.8 | 6.06 | 38 | 55 | 2900 | 5.5 | 2.5 | | 50-250(I) | 25 | 6.94 | 80 | 50 | 2900 | 15 | 2.5 | | 50-250(I)A | 23.4 | 6.5 | 70 | 50 | 2900 | 11 | 2.5 | | 50-250(I)B | 21.6 | 6.0 | 60 | 49 | 2900 | 11 | 2.5 | | 50-315(I) | 25 | 6.94 | 125 | 40 | 2900 | 30 | 2.5 | | 50-315(I)A | 23.7 | 6.58 | 113 | 40 | 2900 | 22 | 2.5 | | 50-315(I)B | 22.5 | 6.25 | 101 | 39 | 2900 | 18.5 | 2.5 | | 50-315(I)C | 20.6 | 5.72 | 85 | 38 | 2900 | 15 | 2.5 | | 65-100 | 25 | 6.94 | 12.5 | 69 | 2900 | 1.5 | 2.5 | | 65-100A | 22.3 | 6.19 | 10 | 67 | 2900 | 1.1 | 2.5 | | 65-125 | 25 | 6.94 | 20 | 68 | 2900 | 3 | 2.5 | | 65-125A | 22.3 | 6.19 | 16 | 66 | 2900 | 2.2 | 2.5 | | 65-160 | 25 | 6.94 | 32 | 63 | 2900 | 4 | 2.5 | | 65-160A | 23.4 | 6.5 | 28 | 62 | 2900 | 4 | 2.5 | | 65-160B | 21.6 | 6.0 | 24 | 58 | 2900 | 3 | 2.5 | | 65-200 | 25 | 6.94 | 50 | 58 | 2900 | 7.5 | 2.5 | | 65-200A | 23.5 | 6.53 | 44 | 57 | 2900 | 7.5 | 2.5 | | 65-200B | 21.8 | 6.06 | 38 | 55 | 2900 | 5.5 | 2.5 | | 65-250 | 25 | 6.94 | 80 | 50 | 2900 | 15 | 2.5 | | 65-250A | 23.4 | 6.5 | 70 | 50 | 2900 | 11 | 2.5 | | 65-250B | 21.6 | 6.0 | 60 | 49 | 2900 | 11 | 2.5 | | 65-315 | 25 | 6.94 | 125 | 40 | 2900 | 30 | 2.5 | | 65-315A | 23.7 | 6.58 | 113 | 40 | 2900 | 22 | 2.5 | | 65-315B | 22.5 | 6.25 | 101 | 39 | 2900 | 18.5 | 2.5 | | 65-315C | 20.6 | 5.72 | 85 | 38 | 2900 | 15 | 2.5 | | 65-100(I) | 50 | 13.9 | 12.5 | 73 | 2900 | 3 | 3.0 | | 65-100(I)A | 44.7 | 12.4 | 10 | 72 | 2900 | 2.2 | 3.0 | | 65-125(I) | 50 | 13.9 | 20 | 72.5 | 2900 | 5.5 | 3.0 |

管道油泵性能参数(3) | 型 号 | 流 量Q | 扬程

(m) | 效率

(%) | 转速

(r/min) | 电机功率

(KW) | 允许汽蚀余量

(m) | | (m3/h) | (l/s) | | 65-125(I)A | 45 | 12.5 | 16 | 71 | 2900 | 4 | 3.0 | | 65-160(I) | 50 | 13.9 | 32 | 71 | 2900 | 7.5 | 3.0 | | 65-160(I)A | 46.7 | 13.0 | 28 | 70 | 2900 | 7.5 | 3.0 | | 65-160(I)B | 43.3 | 12.0 | 24 | 69 | 2900 | 5.5 | 3.0 | | 65-200(I) | 50 | 13.9 | 50 | 67 | 2900 | 15 | 3.0 | | 65-200(I)A | 47 | 13.1 | 44 | 66 | 2900 | 11 | 3.0 | | 65-200(I)B | 43.5 | 12.1 | 38 | 65 | 2900 | 7.5 | 3.0 | | 65-250(I) | 50 | 13.9 | 80 | 59 | 2900 | 22 | 3.0 | | 65-250(I)A | 46.7 | 13.0 | 70 | 59 | 2900 | 18.5 | 3.0 | | 65-250(I)B | 43.3 | 12.0 | 60 | 58 | 2900 | 15 | 3.0 | | 65-315(I) | 50 | 13.9 | 125 | 54 | 2900 | 37 | 3.0 | | 65-315(I)A | 46.5 | 12.9 | 110 | 54 | 2900 | 30 | 3.0 | | 65-315(I)B | 44.5 | 12.4 | 100 | 53 | 2900 | 30 | 3.0 | | 65-315(I)C | 41 | 11.4 | 85 | 51 | 2900 | 22 | 3.0 | | 80-100 | 50 | 13.9 | 12.5 | 73 | 2900 | 3 | 3.0 | | 80-100A | 44.7 | 12.5 | 10 | 72 | 2900 | 2.2 | 3.0 | | 80-125 | 50 | 13.9 | 20 | 72.5 | 2900 | 5.5 | 3.0 | | 80-125A | 45 | 12.5 | 16 | 71 | 2900 | 4 | 3.0 | | 80-160 | 50 | 13.9 | 32 | 71 | 2900 | 7.5 | 3.0 | | 80-160A | 46.7 | 13.0 | 28 | 70 | 2900 | 7.5 | 3.0 | | 80-160B | 43.3 | 12.0 | 24 | 69 | 2900 | 5.5 | 3.0 | | 80-200 | 50 | 13.9 | 50 | 67 | 2900 | 15 | 3.0 | | 80-200A | 47 | 13.1 | 44 | 66 | 2900 | 11 | 3.0 | | 80-200B | 43.5 | 12.1 | 38 | 65 | 2900 | 7.5 | 3.0 | | 80-250 | 50 | 13.9 | 80 | 59 | 2900 | 22 | 3.0 | | 80-250A | 46.7 | 13.0 | 70 | 59 | 2900 | 18.5 | 3.0 | | 80-250B | 43.3 | 12.0 | 60 | 58 | 2900 | 15 | 3.0 | | 80-315 | 50 | 13.9 | 125 | 54 | 2900 | 37 | 3.0 | | 80-315A | 46.5 | 12.9 | 110 | 54 | 2900 | 30 | 3.0 | | 80-315B | 44.5 | 12.4 | 100 | 53 | 2900 | 30 | 3.0 | | 80-315C | 41 | 11.4 | 85 | 51 | 2900 | 22 | 3.0 | | 80-350 | 50 | 13.9 | 150 | 66 | 2900 | 55 | 3.0 | | 80-350A | 44.5 | 12.4 | 142 | 65 | 2900 | 45 | 3.0 | | 80-350B | 41 | 11.4 | 135 | 62 | 2900 | 37 | 3.0 | | 80-100(I) | 100 | 27.8 | 12.5 | 76 | 2900 | 5.5 | 4.5 | | 80-100(I)A | 89 | 24.7 | 10 | 74 | 2900 | 4 | 4.5 | | 80-125(I) | 100 | 27.8 | 20 | 76 | 2900 | 11 | 4.5 | | 80-125(I)A | 89 | 24.7 | 16 | 74 | 2900 | 7.5 | 4.5 | | 80-160(I) | 100 | 27.8 | 32 | 76 | 2900 | 15 | 4.5 | | 80-160(I)A | 93.5 | 26.0 | 28 | 74 | 2900 | 11 | 4.5 | | 80-160(I)B | 86.6 | 24.1 | 24 | 72 | 2900 | 11 | 4.5 | | 80-200(I) | 100 | 27.8 | 50 | 74 | 2900 | 2 | 4.5 | | 80-200(I)A | 93.5 | 26.0 | 44 | 73 | 2900 | 18.5 | 4.5 | | 80-200(I)B | 87 | 24.2 | 38 | 71 | 2900 | 15 | 4.5 | | 80-250(I) | 100 | 27.8 | 80 | 69 | 2900 | 37 | 4.5 | | 80-250(I)A | 93.5 | 26.0 | 70 | 68 | 2900 | 30 | 4.5 | | 80-250(I)B | 87 | 24.2 | 60 | 66 | 2900 | 30 | 4.5 | | 80-315(I) | 100 | 27.8 | 125 | 66 | 2900 | 75 | 4.5 |

立式管道油泵性能参数(4) | 型 号 | 流 量Q | 扬程

(m) | 效率

(%) | 转速

(r/min) | 电机功率

(KW) | 允许汽蚀余量

(m) | | (m3/h) | (l/s) | | 80-315(I)A | 95 | 26.4 | 113 | 66 | 2900 | 55 | 4.0 | | 80-315(I)B | 90 | 25 | 101 | 65 | 2900 | 45 | 4.0 | | 80-315(I)C | 82 | 22.8 | 85 | 63 | 2900 | 37 | 4.0 | | 100-100 | 100 | 27.8 | 12.5 | 76 | 2900 | 5.5 | 4.5 | | 100-100A | 89 | 47 | 10 | 74 | 2900 | 4 | 4.5 | | 100-125 | 100 | 27.8 | 20 | 76 | 2900 | 11 | 4.5 | | 100-125A | 89 | 24.7 | 16 | 74 | 2900 | 7.5 | 4.5 | | 100-160 | 100 | 27.8 | 32 | 76 | 2900 | 15 | 4.5 | | 100-160A | 93.5 | 26.0 | 28 | 74 | 2900 | 11 | 4.5 | | 100-160B | 86.6 | 24.1 | 24 | 72 | 2900 | 11 | 4.5 | | 100-200 | 100 | 27.8 | 50 | 74 | 2900 | 22 | 4.0 | | 100-200A | 93.5 | 26.0 | 44 | 73 | 2900 | 18.5 | 4.0 | | 100-200B | 87 | 24.2 | 38 | 71 | 2900 | 15 | 4.0 | | 100-250 | 100 | 27.8 | 80 | 69 | 2900 | 37 | 4.0 | | 100-250A | 93.5 | 26.0 | 70 | 68 | 2900 | 30 | 4.0 | | 100-250B | 87 | 24.2 | 60 | 66 | 2900 | 30 | 4.0 | | 100-315 | 100 | 27.8 | 125 | 66 | 2900 | 75 | 4.0 | | 100-315A | 95 | 26.4 | 113 | 66 | 2900 | 55 | 4.0 | | 100-315B | 90 | 25 | 101 | 65 | 2900 | 45 | 4.0 | | 100-315C | 82 | 22.8 | 85 | 63 | 2900 | 37 | 4.0 | | 100-100(I) | 160 | 44.4 | 12.5 | 73 | 2900 | 11 | 4.5 | | 100-125(I) | 160 | 44.4 | 20 | 74 | 2900 | 15 | 4.5 | | 100-125(I)A | 140 | 39 | 17 | 72 | 2900 | 11 | 4.5 | | 100-160(I) | 160 | 44.4 | 32 | 32 | 2900 | 22 | 5.6 | | 100-160(I)A | 140 | 39 | 28 | 28 | 2900 | 18.5 | 5.0 | | 100-200(I) | 100 | 44.4 | 50 | 50 | 2900 | 37 | 5.2 | | 100-200(I)A | 140 | 39 | 45 | 45 | 2900 | 30 | 4.5 | | 100-200(I)B | 100 | 27.8 | 40 | 40 | 2900 | 22 | 4.5 | | 100-250(I) | 160 | 44.4 | 80 | 80 | 2900 | 55 | 4.8 | | 100-250(I)A | 140 | 39 | 72 | 72 | 2900 | 45 | 4.5 | | 100-250(I)B | 100 | 27.8 | 65 | 65 | 2900 | 37 | 4.5 | | 100-350 | 100 | 27.8 | 150 | 150 | 2900 | 90 | 4.0 | | 100-350A | 87 | 24.2 | 142 | 142 | 2900 | 75 | 4.0 | | 100-350B | 82 | 22.8 | 135 | 135 | 2900 | 55 | 4.0 | | 125-100 | 160 | 44.4 | 12.5 | 12.5 | 2900 | 11 | 4.0 | | 125-100A | 143 | 39.7 | 10 | 10 | 2900 | 7.5 | 4.0 | | 125-125 | 160 | 44.4 | 20 | 20 | 2900 | 15 | 4.0 | | 125-125A | 143 | 39.7 | 16 | 16 | 2900 | 11 | 4.0 | | 125-160 | 160 | 44.4 | 32 | 32 | 2900 | 22 | 4.0 | | 125-160A | 150 | 41.7 | 28 | 28 | 2900 | 18.5 | 4.0 | | 125-160B | 138 | 38.3 | 24 | 24 | 2900 | 15 | 4.0 | | 125-200 | 160 | 44.4 | 50 | 50 | 2900 | 37 | 5.5 | | 125-200A | 150 | 41.7 | 44 | 44 | 2900 | 30 | 5.5 | | 125-200B | 138 | 38.3 | 37.5 | 37.5 | 2900 | 22 | 5.5 | | 125-250 | 160 | 44.4 | 80 | 80 | 2900 | 55 | 5.0 | | 125-250A | 150 | 41.7 | 70 | 70 | 2900 | 45 | 5.5 |

YG立式管道油泵订货须知:1. YG立式管道油泵产品名称与型号: 2.立式管道油泵进出口径 3. YG立式管道油泵的扬程(m) 4. YG立式管道油泵的流量 5. YG立式管道油泵的电机功率(KW) 6. YG立式管道油泵的转速(r/min) 7.YG立式管道油泵的电机电压(V) 8. YG立式管道油泵的吸程(m) 9. YG立式管道油泵是否带附件以便我们的为您正确选型。 |

6、电机 7、联体座 8、泵盖 9、叶轮螺母 10、泵体 11、放水阀

| 同系列产品

| MORE>> |

|